Tine Harrows

Tine Harrows

New generation

This machine can be used for organic crops but also as an alternative to weed control, soil aeration, growth recovery(depending on the type and equipment chosen)

Its use concerns cereals, corn, beets, rapeseed, potatoes, vegetables, etc.

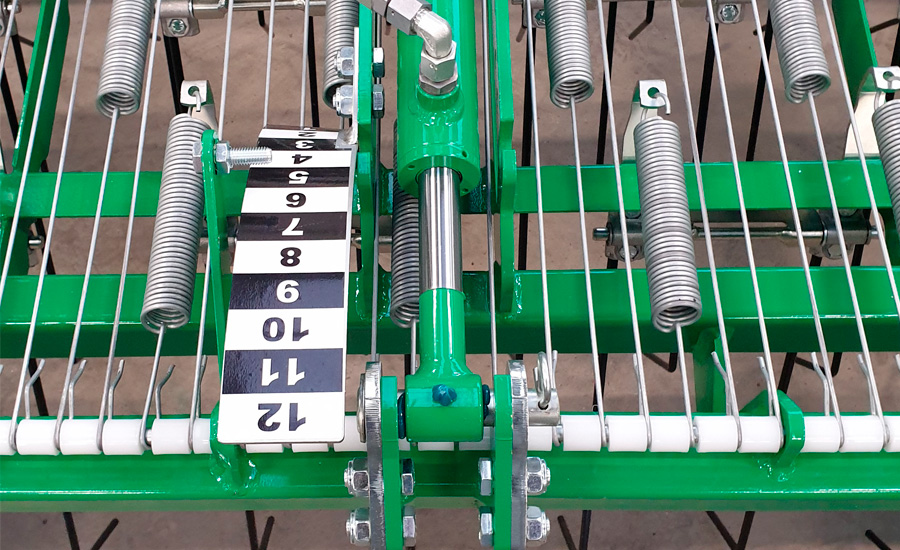

Agronomic Tine Harrows are characterized by a foldable welded frame. Each tines (7 or 8 mm) is independently tensioned by its own spring.

This machine can be used for organic crops but also as an alternative to weed control, soil aeration, growth recovery ((depending on the type and equipment chosen).

Its use concerns cereals, corn, beets, rapeseed, potatoes, vegetables, etc.

Agronomic Tine Harrows are characterized by a foldable welded frame. Each tooth (7 or 8 mm) is independently tensioned by its own spring.

Agronomic Tine Harrows are the only one on the market to have a spring with its stem which forms only one piece. This ensures that you never get tangled when folding or suffer premature wear.

Having one spring per tooth allows for better uniformity of work and a much less “rake” effect compared to an angular panel harrow.

With its 470 mm tine and its spring system above the panel, Agronomic Tine Harrows have the highest clearance under the frame on the market, which allows it to pass through tall crops.

Tines pressure adjustable by mechanical or hydraulic settings.

This machine can be used for organic crops but also as an alternative to weed control, soil aeration, growth recovery ((depending on the type and equipment chosen).

Its use concerns cereals, corn, beets, rapeseed, potatoes, vegetables, etc.

Agronomic Tine Harrows are characterized by a foldable welded frame. Each tooth (7 or 8 mm) is independently tensioned by its own spring.

Agronomic Tine Harrows are the only one on the market to have a spring with its stem which forms only one piece. This ensures that you never get tangled when folding or suffer premature wear.

Having one spring per tooth allows for better uniformity of work and a much less “rake” effect compared to an angular panel harrow.

With its 470 mm tine and its spring system above the panel, Agronomic Tine Harrows have the highest clearance under the frame on the market, which allows it to pass through tall crops.

safety valve

Hydraulic adjustment

Tine angle

Each panel has a manual aggressiveness adjustment, but the hydraulic adjustment option is a real asset.

It allows you to change the setting instantly from the tractor because the type of terrain and the stages of emergence are very rarely uniform across the entire field.

The angle of the tooth is adjusted by the wheels which hold the machine at a height chosen by a simple crank.

On a working width of 12.50 m we have 6 front wheels which keep the machine parallel to the ground.

As an option, 2 rear wheels allow you to control the level of the machine as well as the harrows behind these 2 wheels.

The wheels are Kevlar reinforced which helps prevent punctures.

We chose a heavy frame for two reasons:

• The first is to have a robust and simple chassis

The second is the most important, it is to actually have 4.5 kg of pressure per tooth at maximum pressurehave 4.5 kg of pressure per tooth at maximum pressure. Let’s take the example of a 12.50m Harrow (with option: hydraulic adjustment and rear idlers) which weighs 2.3T divided by 480 teeth. So we actually have 4.8 kg of pressure per tooth.

Aggressiveness is regulated in 2 points. First of all the adjustment of the spring pressure but also by the angle of the tines

It is adjusted with the height of the chassis using the wheels. As a general rule, the tip of the tine must be perpendicular to the ground but it can vary depending on the desired aggressiveness. The more you raise the machine, the more forward the tooth is, the more aggressive it is and vice versa. It is obviously necessary to supplement with spring pressure.

Features of Tine Harrow

| Type of Harrows | 1 m | 1,2 m | 1,6 m | 3,2 m | 6,3 m | 7,5 m | 9,4 m | 12,5 m |

|---|---|---|---|---|---|---|---|---|

| Working width (m) | 1 m | 1,2 m | 1,6 m | 3,2 m | 6,3 m | 7,5 m | 9,4 m | 12,5 m |

| Road gauge (m) | 1 m | 1,2 m | 1,6 m | 3,2 m | 3,2 m | 3,3 m | 3,2 m | 3,3 m |

| Weight (kg) | 200 | 215 | 230 | 500 | 1 000 | 1 200 | 1 500 | 2 000 |

| Number of rows | 6 | |||||||

| Number of tines | 38 | 48 | 60 | 120 | 240 | 288 | 360 | 480 |

| Wheel number and fitment | 2 wheels of 16-650/8 | 4 wheels of 18-950/8 or 16-650/8 | 6 wheels of 18-950/8 | |||||

| Frame | Fixed | Foldable in 2 parts | Foldable into 4 parts | |||||

| Number of element | 1 | 2 | 4 | 6 | 6 | 10 | ||

| Element width | 1 m | 1,20 m | 1,60 m | 1,60 m | 1,60 m | 1,25 m | 1,60 m | 1,25 m |

| Features / Standard Equipment | • 7 mm tines diameter and 470mm length • Double-girder reinforced chassis • Lighting and signage • Depth adjustable by leveling wheel and 3rd point |

|||||||

Option

Tine Harrows

- Rear wheels (pair of 16-650/8) – Size 290/150 mm

- Rear wheels (pair of 18-950/8) – Size 460/230 mm

- Tine behind the rear wheels

- 7 mm tungster carbonate

- Tine diameter 8 mm

- Hydraulic block with control for double folding

Our various product lines

Information Request

Do you have a question about our equipment?

Leave us a message!

Call us.

+33 (0)3 23 22 72 72

Address

16 Bis Grande Rue

02190 AMIFONTAINE / FRANCE

Opening hours

From Monday to Friday

8h-12h / 13h-17h15

agronomic@wanadoo.fr