Multiplant Belt Planters

Agronomic Multiplant Belt Planters

New hopper design and new console

• The multiplant belt planter features a forward planting system.

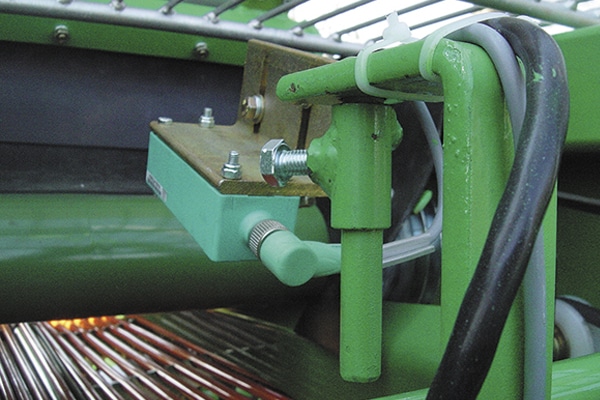

• Ultrasonic sensor for feeding potatoes to the belts.

• 20 belts per element with up-down corrector: automatic adjustment of the position of the belt element so that it remains horizontal regardless of the inclination of the ground.

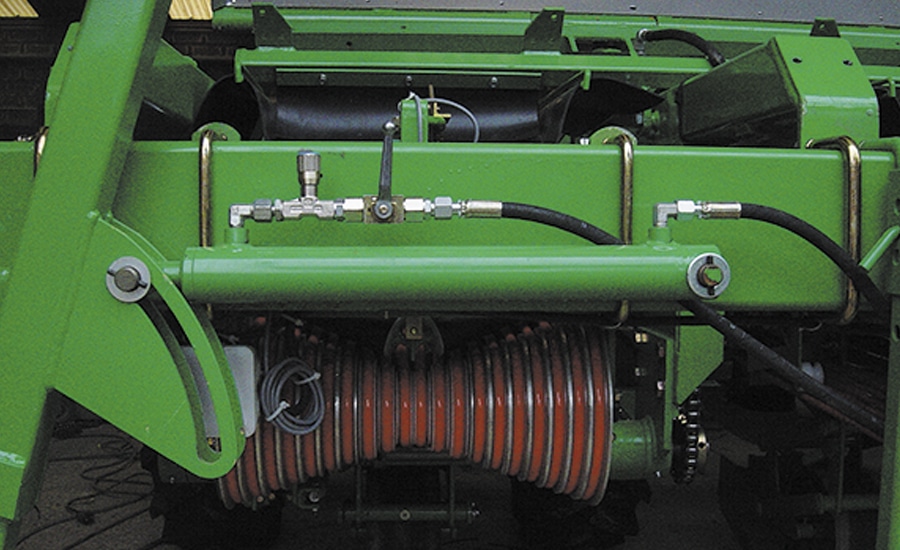

• Hydraulic drive of the belt elements adaptive to the forward speed.

• Progressive mechanical vibrator on each element.

Ultrasonic sensor

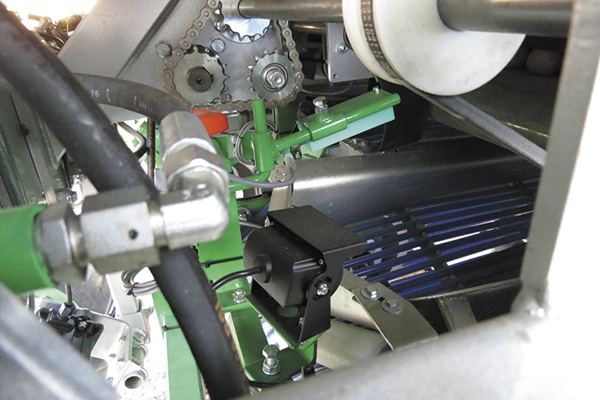

Control camera

• 5-position calibrator on each aluminum element.

• Planting density sensor when potatoes fall: control of planted density in real time.

• Control camera

• Planting setting and counter hectares for hydraulic drive thanks to the cabin computer.

• Auto tilt of the planter element.

• Share dependent on the forming sheet: constant height of soil above the tuber.

• New share model with mechanical or hydraulic pressure.

• INOX forming sheet with adaptive hydraulic pressure.

• Forming sheet with automatic height (optional).

• Hydraulic steering axle on planter with correction of +/- 30% on trailed planter (standard 3 rows trailed ridge and optional on 4 rows).

Automatic adjustment of the belt

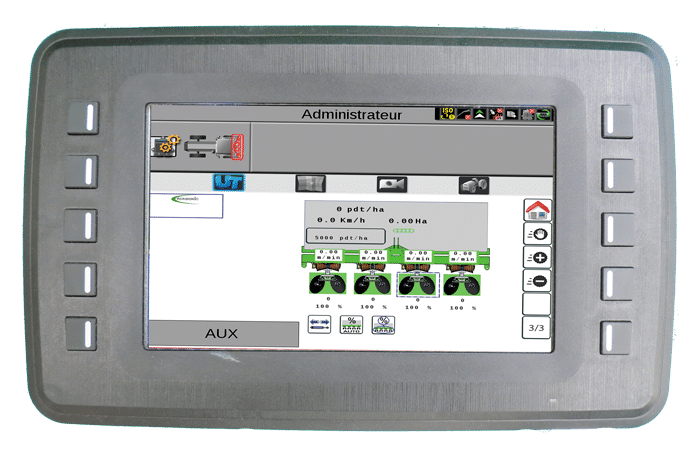

New console

Isobus

New console

New monitor bringing together the functions and settings of the planter.

Advantage of the new console:

Everything is centralized on a single screen, fertilizer localized and spraying are displayed on your single terminal in the cabin.

The terminal is ISOBUS certified and can therefore be directly connected to tractors.

NEW HOPPER DESIGN

Specificity 3 rows of log:

• Offset planting shares for ridge fluidity

• Lateral stainless steel log retaining plate

Contact us for more information.

Features of cup planter

| TECHNICAL SPECIFICATIONS | 2 row range | Reach and drag 4 rows | 3 rows of log | ||

|---|---|---|---|---|---|

| Machine type | 2 RPM | 2 RPM | 4 RMT x 75 | 4 RMP (TH) | 3 XMBI (TH) |

| 2 x 75 | 2 x 90 | 4 tandem wheels | 4 parallel wheels | 2 wheels | |

| Road gauge | 2,4 m | 3,2 m | 3,4 m | 2,5 m | |

| Weight (kg) | 1 500 kg | 1 500 kg | 2 500 kg | 2 100 kg | |

| Distance between rows | 75 cm | 90 cm | 75 cm | 75 cm | 45 cm |

| Wheel type | 7,5 x 16 | 10,5/80 x 18 | 185 x 15 | 7,5 x 16 | 10,5/80 x 18 |

| Number of Wheels | 2 | 4 | 4 | 2 | |

| Hopper Capacity | 800 kg | 1,5 T | 1,5 T (portée) 2,2 T (traînée) | 1,2 T (portée) 2 T (traînée) |

|

| Hopper type | Fixed | Fixed in reach and hydraulic in drag | Hydraulic | ||

| Share type | Suspended shares | Shares attached to the forming sheet | |||

| Type of Counting and training | Electric counting with mechanical drive | Electronic intelligent counting with DPA drive | |||

| Distance between plants | 15 to 65 cm | 15 to 65 cm | 15 to 65 cm | ||

| Features/ Standard equipment | • Discs Ø 510 + Scrapers • Power detector (ultrasonic) • Progressively controlled vibrators • 32-speed gearbox • As standard, the hopper is hydraulic in the trailed version and fixed in the mounted version • Hydraulic tilting of the fixed hopper • Nameplates & lighting • Frontal gateway |

||||

Our various product lines

Information Request

Do you have a question about our equipment?

Leave us a message!

Call us.

+33 (0)3 23 22 72 72

Address

16 Bis Grande Rue

02190 AMIFONTAINE / FRANCE

Opening hours

From Monday to Friday

9h-12h / 14h-18h

agronomic@wanadoo.fr